Chapter 3 is about Radiological air sampling and its an important technique that is used to monitor and assess whether the presence of radioactive particles or gasses are in the air. This process is essential for ensuring the safety of the public, workers, and the environment in areas' that radioactive materials are handled, such as research facilities, medical institutions, or nuclear power plants. Click here to go to the next lesson.

Purpose:

Radiation Protection: To ensure that radiation levels in the air are within acceptable limits and do not pose a risk to human health.

Environmental Monitoring: To assess the impact of radioactive releases on the surrounding environment.

Nuclear Facility Safety: To monitor potential leaks or releases of radioactive materials within nuclear facilities.

Types of Sampling:

Particulate Sampling: Involves capturing solid radioactive particles (e.g., dust, aerosols) suspended in the air. This is often done using air filters or impactors.

Gaseous Sampling: Involves collecting radioactive gases (e.g., noble gases, iodine) from the air using specialized absorbent materials or gas sampling systems.

Sampling Equipment:

Air Samplers: These devices are designed to draw air through sampling media, where radioactive particles or gases are captured.

Filters: High-efficiency particulate air (HEPA) filters are commonly used to collect airborne radioactive particles.

Sorbent Beds: Used to capture radioactive gases. These beds are filled with materials that can adsorb specific radioactive gases.

Sampling Locations:

Sampling locations are strategically chosen to capture air samples from areas of interest, such as near potential sources of radiation or in areas where workers are present.

Sampling Frequency:

The frequency of air sampling depends on the specific requirements of the facility, regulations, and the potential for radioactive releases. Regular and continuous monitoring is often performed, especially in nuclear power plants.

Analysis:

After collecting air samples, they are sent to a laboratory for analysis. Various techniques, including gamma spectroscopy, liquid scintillation counting, and gas chromatography, can be used to determine the type and quantity of radioactive materials present.

Reporting and Regulatory Compliance:

Results from radiological air sampling are reported to relevant regulatory authorities to ensure compliance with safety standards and regulations.

Emergency Response:

Radiological air sampling is an essential component of emergency response plans in case of accidents or incidents involving the release of radioactive materials. Rapid assessment of airborne contamination helps in making informed decisions about evacuations and protective measures.

Calibration and Quality Assurance:

To ensure the accuracy and reliability of air sampling results, calibration and quality assurance programs are implemented, including regular equipment maintenance and performance checks.

Radiological air sampling plays a critical role in safeguarding against the harmful effects of radiation exposure and maintaining the safety of nuclear facilities and the surrounding environment. It helps ensure that radiation levels are well-monitored and controlled to prevent health risks.

This procedure describes when air samples must be

collected and the processes for sample collection, determining airborne

concentrations, and taking appropriate actions based on analytical

results. Sampling methods are described

for airborne particulates, iodine and noble gas.

This procedure

describes processes that supplemental RP personnel perform to assess

radiological hazards from airborne radioactivity. Generic instructions are provided to enable

supplemental personnel to sample and assess airborne hazards with air samplers

and counting instruments typically used in the industry. Site-specific training is required if

supplemental personnel are expected to perform gamma spectroscopy analysis or

use programmed instruments that simultaneously count both alpha and beta

radiation.

Instructions are

provided to analyze particulate air samples to determine the following:

·

A DAC fraction from beta-gamma emitters using a

counting system and assuming the total activity is Co-60, or other nuclide(s)

as directed by site procedures.

·

A βγ/α Ratio when required by this

procedure.

·

An estimate of the total DAC fraction, including

transuranics, assuming all alpha emitting activity measured with a counting

system is Am-241, or other nuclide(s) as directed by site procedures.

·

An estimate of the total DAC fraction, including

transuranics, if required by the site in lieu of completing an alpha

analysis. If such estimates are

required, the site is responsible for specifying a TRU multiplier based on site

characterization and/or conservative assumptions. This procedure does not provide instructions

for site characterization.

This procedure does not provide instructions

for sampling tritium, analyzing iodine sample cartridges, or analyzing noble

gas samples since these are tasks that are rarely performed by supplemental

personnel. Site specific training and

qualification should be performed if supplemental personnel are expected to

sample for tritium or analyze iodine sample cartridges or noble gas samples.

The forms referenced by

this procedure are examples used to describe the pertinent information that

should be recorded for future reference.

Plant procedures may specify the use of equivalent forms or the use of

electronic media for the same purposes.

Calculations described

in this procedure are provided to define how sample parameters are used to

evaluate the magnitude and significance of airborne radioactivity. Site procedures may use alternative

equations, provide graphs to substitute for calculations, direct the use of

software for the same purposes, and/or authorize only site personnel to perform

calculations.

Member utilities are

expected to use this standard to enable supplemental workers to transition

between nuclear power plants with minimal site-specific training. Compliance with these instructions is

expected without additional site requirements or process deviations being

imposed that may require additional training or challenge the performance of

supplemental workers.

This procedure is used

to train and instruct supplemental radiological protection technicians. Member utilities will implement these process

requirements in site procedures and update site procedures whenever

requirements or process steps in this Nuclear Industry Standard Process (NISP)

are revised. Current revisions are

maintained on the INPO website.

Terms and definitions

not defined in this procedure are provided in NISP-RP-13, Radiological Protection Glossary.

Clarifying notes for requirements and

process steps are provided in Section 4.0 using superscript numbers in sections

2.0 and 3.0.

2.1

Evaluation of air sample results requires

comparison of airborne concentrations to the Derived Air Concentration (DAC)

values in 10 CFR 20, Appendix B. The

following terminology is used in describing the overall process in this

procedure.

2.1.1

βγ/α Ratio – The total activity of

beta-gamma emitters divided by the total activity of transuranic alpha emitters

as measured by counting systems. An

increasing presence of transuranics is indicated by a decreasing ratio. The term is called an Activity Ratio or the

Beta-Gamma to Alpha Ratio.

2.1.2

fDACβγ – The sum of

each beta-gamma emitting nuclide’s activity divided by its corresponding DAC

value; the term is called the Beta-Gamma DAC Fraction. In some cases, the total beta-gamma activity

may be divided by the most restrictive nuclide (e.g. Co-60 or Cs-137) for an

approximation of the Beta-Gamma DAC Fraction.

2.1.3

fDACα

– The sum of each alpha emitting nuclide’s activity divided by its

corresponding DAC value; the term is called the Alpha DAC Fraction. In some cases, the total alpha activity may

be divided by the most restrictive nuclide DAC value (e.g. Am-241) for an

approximation of the Alpha DAC Fraction.

2.1.4

fDACTotal – The sum

of fDACβγ and fDACα; the term is

called the Total DAC Fraction.

2.1.5

DACFractionRatio

– The ratio of fDACα/ fDACβγ; the term is called the DAC Fraction Ratio. This ratio shows the relative significance of

transuranics in contributing to potential internal dose to workers. This value can be determined using

conservative assumptions for the nuclides present or use nuclide abundances

from site characterization as described in Reference 5.1.

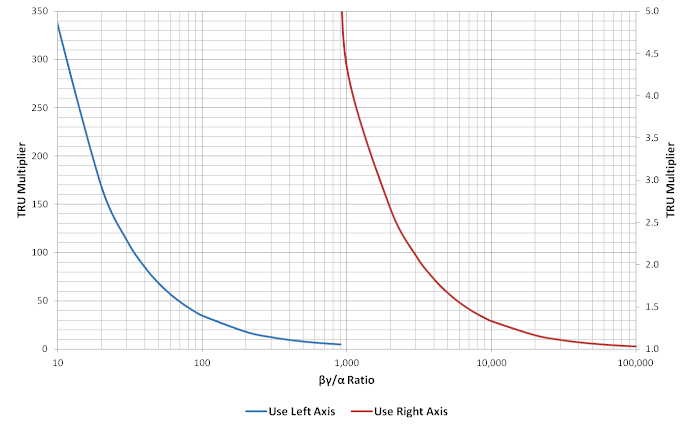

2.1.6

TRU Multiplier – A value equal to 1 + DACFractionRatio that can be

multiplied by the fDACβγ to estimate the fDACTotal

in lieu of completing an alpha analysis.

A graph showing TRU Multiplier values based on βγ/α Ratios,

assuming Co-60 and Am-241, is provided in Attachment 3.

2.2

Air samples are classified based on the location

and purpose for collecting the sample as follows:

2.2.1

Breathing Zone Air Sample – An air sample where

the filter media is within approximately 12 inches of a worker’s head1.

a. A

personal air sampler is set up with the filter media within a 25 cm (10 inches)

radius of the worker’s nose and mouth (Reference 5.1).

b. A

lapel air sampler should be used if the results will be used to assign dose to

a worker.

2.2.2

Work Area Air Sample – An air sample where the

filter media is located to provide an average measurement of airborne radioactivity

to which workers are exposed in a work area.

a. Either

grab samples or continuous sampling may be used provided sample volumes are

controlled to obtain an MDA less than 0.3 DAC for the nuclides being sampled.

b. Place

sampling media as close to the breathing zone as practicable without

interfering with the work or the worker.

c. Place

the sampling media downstream of the airborne source if airflow patterns may

affect dispersion.

2.2.3

General Area Air Sample – An air sample located

to accomplish one or more of the following:

a. Determine

potential airborne hazards.

b. Verify

postings and boundaries.

c. Determine

the effectiveness of engineering controls.

d. Measure

general or average concentrations.

e. Detect

unexpected releases into a workplace.

2.3

Plant RP organizations are responsible for

categorizing plant systems and areas based on the potential contribution of

transuranics to the internal dose of workers.

Categories are defined as follows:

2.3.1

Alpha Level 1 Area – The internal dose from

alpha emitting transuranics is not likely to exceed 10% of the total internal

dose from inhalation. Alpha Level 1

Areas have a βγ/α Ratio greater than 30,000 or

alpha activity levels are less than 20 dpm/100 cm2. An area not posted as an Alpha Level 2 or 3

Area is an Alpha Level 1 Area. Postings

are not required for an Alpha Level 1 Area.

2.3.2

Alpha Level 2 Area – Alpha emitting transuranics

are likely to contribute between 10% and 90% of the total internal dose from

inhalation. Alpha Level 2 Areas have a βγ/α Ratio between 300 and 30,000.

Alpha Level 2 Areas are posted per NISP-RP-04, Posting and Labeling of Radiological Areas.

2.3.3

Alpha Level 3 Area – The internal dose from

alpha emitting transuranics is likely to exceed 90% of the total internal dose

from inhalation. Alpha Level 3 Areas

have a βγ/α Ratio less than 300. Alpha

Level 3 Areas are posted per NISP-RP-04.

2.4

Analyze a particulate air sample for alpha

emitting transuranics using the following criteria:

2.4.1

An air sample measures a fDACβγ ≥ 1.0 DAC.

2.4.2

As required by the option used by the site as described

in Attachment 4 for Alpha Level 2 Areas.

2.4.3

An air sample was collected in an Alpha Level 3

Area.

2.5

Prejob planning should ensure personnel

collecting air samples understand the following:

2.5.1

When samples are needed based on the conditions

listed in section 3.1 of this procedure.

2.5.2

Required breathing zone, work area, and general

area air samples.

2.5.3

Minimum sample volumes required by site

procedures. Typical requirements for

sample volume are provided below:

a. Sample

250 liters (8.8 ft3) for corrosion and fission products.

1) A

250 liter sample can collect a sufficient amount of Co-60 to measure 0.3 DAC if

the counting system has an MDA less than 1,600 dpm of Co-60.

b. Sample

1,000 liters (35.3 ft3) for transuranics.

1) A

1,000 liter sample can collect a sufficient amount of Am-241 to measure 0.3 DAC

if the counting system has an MDA of 2.8 dpm and there is negligible

self-absorption within the sample filter.2

2.6

Air samples should be collected to evaluate the

airborne hazards due to the specific work activities performed.

2.6.1

Collect grab samples during expected periods of

actual or potentially highest airborne concentrations and evaluate them as

quickly as practicable to determine the need for adjusting engineering

controls, respirators, area evacuation, area posting, or worker relief from

unnecessary respirator use.

2.6.2

For work that has the potential to generate

airborne radioactivity for a longer period of time, e.g. over an hour, operate

an air sampler continuously while work is in progress.

a. Change

out filters with the objective to evaluate sample results from specific

activities more likely to generate airborne radioactivity, e.g. a system

breach, lapping of a valve seat, decontamination, etc.

2.7

Review and comply with site procedures for the

issue and return of air sampling equipment and portable instruments.

2.8

Always inspect air sampling equipment and sample

media prior to use to ensure the following, as applicable:

2.8.1

Physical damage does not exist that could affect

operation.

2.8.2

Sample pumps have been calibrated within the

required time frame.

2.8.3

Any batteries that are required are charged for

operation.

2.8.4

Any AC power cords are not damaged and AC power

is available where the sample will be taken.

2.8.5

Operability is checked by starting the sampler

and observing expected parameters.

2.8.6

Sample holders or Marinelli beakers are not

damaged.

2.8.7

Sample holders do not have any cracked or

missing O-rings or screens.

2.8.8

Threads and connectors are not damaged and

function as expected.

2.8.9

The age of filter media has not exceeded a

required shelf-life, e.g. iodine cartridges.

2.9

Avoid placing sampler motors directly on

contaminated surfaces (e.g. greater than 10,000 dpm/100 cm2) where

the motor exhaust could create airborne radioactivity.

2.9.1

Consider covering the surface or suspending the

sampler motor to minimize the potential for airborne.

2.10 Do

not use electrical devices in atmospheres that may be approaching the Lower

Explosive Limit, e.g. 2% to 4% H2.

2.11 Exercise

care to prevent cross contamination of sample filters during the removal and

bagging process.

2.12 If

air sample results indicate airborne concentrations exceeded 0.3 DAC, or a

personal air sampler indicates an intake could occur greater than 4 DAC-hours,

in an area that is not posted and controlled as an Airborne Radioactivity Area,

take the following actions:

2.12.1 If

radon interference is suspected during field analysis, consult RP supervision

to determine if follow-up actions should be delayed until a

radon-discriminating analysis is completed.

2.12.2 Stop

work, evacuate workers from the affected area, and collect grab samples to determine

if airborne concentrations are sustained and to identify the source if unknown.

2.12.3 Inform

workers in the area without respiratory protection that airborne radioactivity

was measured and potential exposures will be evaluated.

2.12.4 If

the conditions causing the airborne radioactivity may still exist or are

unknown, immediately post and control the area as an Airborne Radioactivity

Area.

2.12.5 Notify

RP supervision and ensure the occurrence is documented in the plant corrective

action program to identify the cause of the conditions and any corrective

actions, including an assessment of potential doses to workers.

3.0

Process Instructions

The

basic process for air sampling is to obtain a sample, analyze the sample, and

then take the appropriate actions if airborne concentrations exceed 0.3

DAC. Appropriate actions include

ensuring the area is posted as an Airborne Radioactivity Area per NISP-RP-04, Radiological Posting and Labeling and to

determine cause and corrective actions if the airborne radioactivity was not anticipated. The analysis portion of this process for a

particulate filter has additional steps to determine the abundance of alpha

emitting transuranic nuclides in the airborne mixture. The process diagram below provides the

standard process for analysis of a particulate air sample filter. Attachments 1 and 2 provide more detailed

instructions to complete this process.

3.1

Determine the Need for an Air Sample

3.1.1 Comply

with the air sampling requirements as stated in plant procedures, RWPs, ALARA

Plans or as directed by RP supervision.

a. Notify

RP supervision if an activity may warrant air sampling but the need for an air

sample has not been identified.

3.1.2 Collect

work area air samples whenever respiratory protective equipment is worn to

validate that the protection factor was sufficient to limit the intake of

radioactive material.

3.1.3 Use

the following guidelines to identify the need for an air sample.

a. During

any work or operation that is known to have a potential for causing airborne

radioactivity such as:

1) Grinding,

welding, burning, cutting, hydrolasing, vacuuming, sweeping, or using

compressed air on contaminated equipment.

2) Using

volatile substances on contaminated surfaces.

3) When

compacting waste.

4) When

removing contaminated insulation.

b. During

any work or operation that involves the breach of a radioactive system for

which the potential for measurable airborne radioactivity is known to exist.

c. Prior

to or during initial entry into a known or suspected airborne radioactivity

area such as:

1) Steam

leaks from a primary system.

2) Steam

leaks from a BWR secondary system.

3) Leaks

from a BWR off-gas systems

4) Leaks

from a gaseous waste processing system.

d. When

working in an area with levels of dry removable contamination that could become

suspended in concentrations greater than 0.3 DAC such as:

1) Greater

than 100,000 dpm/100 cm2 of βγ

emitting nuclides.

2) When

aggressive work (e.g. cutting, grinding, welding, etc.) is performed in Alpha

Level 2 Areas or on systems with suspected but unknown amounts of

transuranics.

3) Work

in Alpha Level 3 Areas.

e. Initial

entry into a PWR containment or BWR drywell during power operation with

subsequent air samples as directed by RP supervision.

f.

Initial entry into a PWR containment or BWR

drywell following shutdown as directed by RP supervision.

g. Prior

to or during initial entry into any high-risk area such as steam generators,

reactor cavities, reactor vessels, or radioactive waste tanks, and periodically

thereafter.

h. When

environmental factors such as heat, air flows, low humidity, etc. increase the

potential for highly contaminated surfaces, components, and filters to dry and

the contamination to become suspended in air.

i.

A significant spill or spread of contamination

has occurred.

j.

System leakage or work activities can result in

airborne radioactivity and an area sample is needed to provide a timely alert

of the changing condition.

k. When

DAC-Hour tracking is used to monitor worker intakes.

l.

When fuel leaks have occurred elevating noble

gas, iodine, and transuranic nuclides in the RCS. Plant-specific procedures are used in

response to fuel failure to monitor potential doses to workers.

m. A

potential airborne pathway exists for a release to the environment. Consult with personnel responsible for

effluent monitoring to ensure appropriate locations and parameters are

established for airborne monitoring.

3.2

Collect a Particulate and Iodine Air Sample

WARNING

Do not use electrical

devices in atmospheres that may be approaching the Lower Explosive Limit, e.g.

2% to 4% H2.

3.2.4 Use

an iodine sampling cartridge as required by site RP supervision, RWPs and/or

ALARA Plans.

a. Site

RP management may discontinue sampling for iodine when sample trends show that

iodine is not a concern.

b. Use

silver zeolite cartridges in noble gas atmospheres when directed by RP

supervision.

1) Ensure,

through prejob planning, that hydrogen is not present when using a silver

zeolite cartridge per Reference 5.2.

3.2.5 Select

an appropriate sampling method considering the following:

a. Use

a grab sampler to obtain an air sample in a short period of time.

1) Grab

samples are used to quickly verify airborne concentrations during a system

breach, monitor work area concentrations for short duration work, or in

conjunction with low volume air samplers to determine peak airborne

concentrations.

b. Use

a continuous air sampler to collect samples over a longer period of time such

as the entire duration of the work or continuously for routine verification

that airborne radioactivity is not present.

c. Use

a sample head connected to a remote pump with tubing when conditions limit

placing the air pump at the sampling location.

1) Refer

to site procedures to determine the allowable length of tubing.

2) Avoid

the use of tubing prior to the inlet of the sample head due to potential plate

out of radioactive material in the tubing prior to the air entering the filter

media.

3.2.6 Obtain

the appropriate air sampling pump for the type of sampling required.

3.2.7 Follow

the guidelines in Attachment 5 to set up and operate the sampler.

3.2.8 Inspect

the equipment to ensure it is operable and reliable.

3.2.9 Load

the particulate filter and iodine cartridge7 in the sample holder.

a. Ensure

filters are aligned or marked as needed to indicate the collection side that

should face the detector during analysis.

3.2.10 Position

the air sample filters as needed for a breathing zone, work area, or general

area sample and commence operation of the sampler to coincide with the activities

expected to generate airborne radioactivity.

a. Collect

a minimum volume as specified in section 2.5.3 of this procedure unless

otherwise specified by work instructions, the RWP, ALARA Plan, or RP

supervision.

3.2.11 Exercise

care to prevent cross contamination of the filters during the removal and

bagging process.

3.2.12 Complete

Attachment 1 (or site equivalent form) to record important sample parameters

for required analyses.

3.2.13 If

the sample was obtained in a noble gas atmosphere, consider purging the gas

from the sample media by running the sampler 1 to 2 minutes in an area where

noble gas, airborne particulates, or iodine are not present.

3.3

Collect a Noble Gas Sample

3.3.14 Open

the lid of a Marinelli and wave the Marinelli in the atmosphere for 15 to 30

seconds to allow the Marinelli contents to equilibrate with the atmosphere.

a. Place

and seal the lid on the Marinelli prior to leaving the sampling area.

3.3.15 Use

water displacement to collect noble gas.

a. Obtain

a 1 liter or 4 liter Marinelli beaker approved for gamma spectroscopy that has

a removable lid.

b. Fill

the container completely with demineralized water and seal the container.

c. Proceed

to the area where the sample is to be collected, open the container, pour the

water into a floor drain or another container, and re-seal the sample

container.

d. Complete

Attachment 1 (or site equivalent form) to record important sample parameters

for required analyses.

3.3.16 Use

a sample pump to collect noble gas per site procedures. Generic steps are listed below.

a. Obtain

a 1 liter or 4 liter Marinelli beaker that has stopcocks and is approved for

gamma spectroscopy.

b. Obtain

a low flow air pump (e.g. 15

lpm).

c. Perform

an inspection to ensure the equipment is operable.

d. Connect

the sample pump to the sample container with vacuum tubing.

e. Open

the valves on the container and start the sample pump.

f.

Allow a sufficient purge time to totally

displace the container volume with the sampled atmosphere (e.g., for a 4 liter

container, a volume of at least 20 liters is needed).

g. Stop

the pump and close the inlet and outlet valves.

h. Complete

Attachment 1 (or site equivalent form) to record important sample parameters

for required analyses.

i.

Submit the sample for gamma spectroscopy

analysis.

3.4

Operate a Continuous Air Monitor (CAM)

3.4.17 When

assigned responsibility to monitor or maintain a CAM, ensure prejob planning

activities provide instructions for the following:

a. Identification

of status lights that indicate normal operation.

b. Identification

of status lights and any alarms that indicate increased airborne

concentrations.

c. The

proper sequence for manipulating the CAM to change out filters.

3.4.18 Take

the following actions if an unexpected alarm occurs from a continuous air

monitor.

a. If

a work activity is causing increased airborne radioactivity in the area, stop

work and evacuate workers from the immediate area.

b. Collect

grab air samples for confirmation of airborne concentrations.

c. If

it is unlikely that a work activity is causing increased airborne

radioactivity, survey the area to determine if an increase in background

radiation levels caused the alarm.

d. Notify

RP supervision of the alarm and known conditions for further direction.

3.5

Set Up and Operate a Personal Air Sampler

3.5.19 Issue

personal air samplers as required by the RWP.

3.5.20 Issue

personal air samplers to each worker in an Alpha Level 2 or 3 Area based on the

following criteria:

a. Work

in Alpha Level 3 Areas.

b. Aggressive

work in Alpha Level 2 Areas or on systems with suspected but unknown amounts of

transuranics.

1) Examples

of aggressive work include cutting, grinding, welding, etc.

c. Exceptions

may be made for the following:

1) When

air supplied suits are worn if the industrial hazards associated with the use

of a personal air sampler outweigh the benefits.

2) Where

a periodic (non-incident based) alpha excreta sampling program is in place.

3) During

a specific task evolution where it is concluded that a personal air sampler is

not necessary, because the potential for airborne alpha had been evaluated and

is considered improbable, and appropriate stop work controls are in place and

communicated to the workers.

4) Where

engineering controls, (e.g. a glove box) adequately contain the source term.

3.5.21 Ensure

work area sampling is also performed where personal air samplers are in use to

provide a complete assessment of the airborne hazard.

a. Measurements

from a personal air sampler are not reliable for a complete hazard assessment,

including posting criteria, due to:

1) Difficulties

in controlling the sampling volume required to measure 0.3 DAC.

2) Potential

movement of the workers in and out of the area with the highest airborne

radioactivity.

3.5.22 Perform

the following steps when setting up the personal air sampler for use:

a. Attach

the pump to the worker using the belt that is provided.

b. Secure

the tygon tubing with the air sampler head over the worker’s shoulder and neck.

c. Locate

the sampler head within 10 inches of the workers nose and mouth.

d. Secure

the air sample head to the worker by tape or other means making sure not to

restrict air flow through the tube.

e. Turn

the pump on and verify the flow rate is within specification.

f.

Inform the worker to leave the work area if they

believe the pump is turned off for more than 30 seconds or is otherwise

malfunctioning.

g. Document

the person’s name and any other identifying information on the site-specific

document (e.g. air sample bag or an accompanying form) along with the time the

pump was turned on and any other pertinent information such as flow rate, job

location time, etc.

3.5.23 Perform

the following steps when removing a personal air sampler:

a. Turn

off the sampler pump.

b. Remove

the air sampler head, tygon tubing, and pump from the worker.

c. Remove

the air sample from the air sample head and place in the air sample bag or

petri dish as required by site procedures.

d. Use

site-specific procedures and forms to record parameters and analyses.

3.6

Analyze a Particulate Air Sample Filter

3.6.24 Use

Attachment 1 to record air sample parameters that are required to calculate

airborne concentrations.

a. Use

site-specific forms to record sample parameters from a personal air sampler to

calculate a potential intake.

3.6.25 Use

Attachment 1 and the instructions in Attachment 2 to analyze air sample filters

and compare airborne concentrations to Derived Air Concentrations (DAC).

5.13 EPRI

Alpha Monitoring Guidelines for Operating Nuclear Power Stations, Revision 2,

EPRI Technical Report 3002000409, August 2013

5.14 NRC

Information Notice No. 86-43: Problems

with Silver Zeolite Sampling of Airborne Radioiodine

5.15 NRC

Regulatory Guide 8.25, Air Sampling in the Workplace, Revision 1, §3.1

5.16 NISP-RP-13,Radiological Protection Glossary

5.17 NISP-RP-04,Posting and Labeling of Radiological Areas

5.18 NISP-RP-10,Radiological Job Coverage

5.19

Attachment 1: Airborne Radioactivity Calculation Worksheet

– Sample

Each parenthetical number on the worksheet corresponds

to instructions in Attachment 2.

|

Section I:

Air Sample Collection Information |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(1) Location/Description: |

RWP: |

|

(2) |

Air Sampler

Type: |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Survey #: |

|

Serial Number: |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Sampled by: |

|

Cal Due Date: |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(3) Reason for Sample: |

|

(4) |

¨ Grab Sample |

¨ Continuous Sample |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(5) |

¨ Breathing Zone |

¨ Work Area |

¨ General Area |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(6) |

Sample

Start |

Sample Stop |

Total Time (minutes) |

Flow Rate |

Total Volume |

Total Volume (ml) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Start |

Stop |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Date: |

Date: |

|

|

|

cfm |

ft3 |

x 28,320 = |

ml |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Time: |

Time: |

|

|

|

lpm |

liters |

x 1,000 = |

ml |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(7)Sample Collected From: |

¨ Alpha Level 1 Area |

¨ Alpha Level 2 Area |

¨ Alpha Level 3 Area |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(8) |

NOTE: Use a TRU Multiplier only if an estimate of

fDACTotal is needed in

lieu of completing alpha analysis. |

βγ/α Ratio: |

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

TRU Multiplier: |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(9) |

Analyses Requested |

¨ Gamma spec (Part and/or Iodine) |

¨ Noble Gas |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

¨ Beta-Gamma Analysis |

¨ Alpha Analysis |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Section II:

Beta-Gamma (βγ) Analysis |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

βγ

Analysis |

Date/Time |

ncpm |

dpm |

fDACβγ |

RPT Initials |

Serial Number |

Cal. Due Date |

Eff |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(10) |

1.0

Initial |

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2.0

(11) |

3.0

Follow-Up |

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(12) fDACTotal if Needed in Lieu of Alpha Analysis (fDACβγ X TRU Multiplier): |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Section III:

Alpha (α) Analysis |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4.0

α Analysis |

Date/Time |

ncpm |

dpm |

Βγ/α Ratio |

fDACα |

RPT Initials |

Serial Number |

Cal. Due Date |

Eff |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

5.0

(13) |

6.0

Initial |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

7.0

(14) |

8.0

Follow-Up |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

9.0

(15) |

10.0 Rn Comp |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(16) |

Long-Lived |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Section IV: Final Summary |

|

(17)fDACβγ

= |

|

|

(18)fDACα

= |

|

|

(19) fDACTotal = |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(20)Reviewed

by: |

|

|

Approved by: |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Print/Sign |

|

|

Print/Sign |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Attachment 2: Instructions to Complete Airborne

Radioactivity Worksheet

Section I:

Air Sample Collection Information

Complete this section for each air sample except samples

from personal air samplers. Use

site-specific procedures and forms for recording parameters and analyses of

personal air samples.

(1) Record

sufficient information to describe where the sample was taken, the RWP number

for the work at the sampling location, the survey number documenting the final

results, and the printed name of the RP technician collecting the sample.

(2) Record

the type of sampler, e.g. hi-volume, lo-volume, gas, etc., the serial number of

the sampler, and the calibration due date.

(3) Record

the reason for the sample, e.g. job coverage, system breach, HEPA maintenance,

etc.

(4) Check

the applicable box for one of the following:

a. Grab

Sample – A short duration sample to measure the airborne concentration at a

single moment in time.

b. Continuous

Sample – A sample taken to measure the average airborne radioactivity over a

period of time; continuous samples are typically collected from 30 minutes to

several hours.

(5)

Check the applicable box for:

a. Breathing

Zone

b. Work

Area Sample

c. General

Area Sample

(6)

Record the sample collection data required to

determine the total volume of air sampled.

Record “n/a” if a sample pump was not used, e.g. a noble gas grab

sample.

a. Record

the date and time for starting and stopping the sampler and the total time for

sampling in minutes.

b. Record

the flow rate at the start and end of the sampling period. Record the average flow rate of the sampler.

c. Calculate

and record the total volume sampled.

d. Record

the total volume in ml.

(7)

Check the box showing the classification of the

area where the sample was collected: Alpha Level 1 Area, Alpha Level 2 Area, or

Alpha Level 3 Area.

(8)

Record the βγ/α Ratio

and, if an estimate of fDACTotal is needed

in lieu of completing an alpha analysis, the Transuranic (TRU) Multiplier

applicable to the air sample. These

values may be obtained using Attachment 3 or provided by RP supervision based

on site characterization. The Total DAC

is determined by multiplying the fDACβγ by the TRU

Multiplier. A TRU Multiplier is

derived as follows.

(9) Use

this section to check the types of analysis needed. Samples may be submitted to a laboratory for

all analyses or technicians may complete all or portions of the Beta Analysis

and/or Alpha Analysis sections prior to submittal to the laboratory.

Attachment 2: Instructions to Complete Airborne

Radioactivity Worksheet (continued)

Section II:

Beta-Gamma (βγ)

Analysis

Use this section to document an initial screening

of the sample using a beta detector with either a scaler or ratemeter. This section is not required if the sample

has been submitted to the laboratory for gamma spectroscopy.

(10) Record

data in the row designated for an initial βγ analysis to record data from the first analysis performed

after the sample was collected.

a.

Record the following information:

·

Date and time of the analysis

·

Serial number of the instrument

·

Calibration due date

·

Efficiency factor (use 0.1 for a pancake GM

detector unless otherwise instructed by RP supervision)

b. If

using a gas flow proportional counter or other instrument, record the efficiency

factor posted with the specific instrument.

c. Record

the net counts per minute (ncpm) above background. Ensure background is less than 200 cpm when using a pancake GM detector.

·

Record ND (for not detected) if there is not an

observable count rate above background or scaler counts are below the MDA value

posted with the instrument.

d.

Divide the observed ncpm by the efficiency and

record the dpm value.

·

Record ND if there is not an observable count

rate above background or scaler counts are below the MDA value posted with the

instrument.

e.

Use the following equation to calculate fDACβγ

if activity is detected above background.

RP supervision may direct using a different DAC value based on the plant

source term. Use an equation as directed

by RP supervision.

|

where: |

|

|

0.0222= |

(2.22e+6 dpm/µCi) X (1e-8 µCi/ml) |

|

1e-8= |

DAC value for Co-60 |

f. If

fDACβγ

is ≥ 0.3 DAC, notify RP

supervision and collaborate to accomplish or verify the following:

·

If radon interference is suspected during field

analysis, consult RP supervision to determine if follow-up actions should be

delayed until a radon-discriminating analysis is completed.

·

Ensure the area is properly posted as an

Airborne Radioactivity Area per NISP-RP-04.

·

Submit the sample and worksheet to the

laboratory for gamma spectroscopy analysis with a priority as established by RP

supervision.

·

Determine cause and corrective action if the

airborne radioactivity was not anticipated.

Attachment 2: Instructions to Complete Airborne

Radioactivity Worksheet (continued)

g. Complete

the following Section III for alpha analysis for any one of the following

conditions:

·

The fDACβγ is ≥ 1.0.

·

The

sample was from an Alpha Level 2 Area and an alpha analysis is required as

determined using Attachment 4.

·

The sample was from an Alpha Level 3 Area.

(11) Record

data in the row designated for a follow-up βγ analysis as an option to determine if the initial results

were impacted by the presence of radon daughters.

a.

Perform the follow-up analysis approximately 30

minutes to 1 hour after the initial analysis.

Perform the same steps as described for an initial analysis.

b.

Any observed decay indicates the presence of

short-lived radon daughters. The

half-life of radon daughters ranges from 35 to 40 minutes depending on the time

after sample collection.

c.

If the results are affected by radon daughters,

submit the sample and worksheet to the laboratory for analysis using gamma

spectroscopy or alternative with a priority as established by RP supervision.

(12) If

the sample was collected in an Alpha Level 2 or 3 Area, multiply fDACβγ

by the TRU Multiplier to approximate fDACTotal if an

estimate is needed in lieu of completing alpha analysis.

Section

III: Alpha (α) Analysis

Use this section to document an analysis performed

with an alpha detector using a scaler. This section is used to determine the βγ/α ratio for a sample collected from an Alpha Level 3 Area,

Alpha Level 2 Area, or an Alpha Level 1 Area when fDACβγ is ≥

1.0.

(13) Record

data in the row designated for an initial α analysis to record data from the first analysis performed

after the sample was collected.

a.

Record the date and time of the analysis, the

serial number of the instrument, the calibration due date, and the initials of

the RP technician performing the analysis.

b.

Record the efficiency factor as posted with the

instrument. Ensure the efficiency factor

includes the self-absorption factor for the filter media being analyzed.

c.

Record the net counts per minute (ncpm) above

background.

·

Record ND (for not detected) if counts are below

the MDA value posted with the instrument.

d. Divide

the observed ncpm by the efficiency and record the dpm value.

·

Record ND if counts are below the MDA value

posted with the instrument. No further

analyses are required. Record less than

0.1 for values of fDACα.

e.

Calculate and record the βγ/α Ratio by

dividing the dpm value from the βγ

Analysis (or gamma spectroscopy results) by the dpm value from the α Analysis.

Attachment 2: Instructions to Complete Airborne

Radioactivity Worksheet (continued)

f. Use

the following equation to calculate fDACα. RP supervision may direct using a different

DAC value based on the plant source term.

Use an equation as directed by RP supervision.

|

where: |

|

|

6.66e-6= |

(2.22e+6 dpm/µCi) X (3e-12 µCi/ml) |

|

3e-12= |

DAC value for Am-241 |

(14) Record

data in the row designated for a follow-up analysis using the same steps as

described for the initial α

analysis to determine if short-lived radon daughters are present. If radon daughter contribution is suspected,

perform this follow-up count 1 to 2 hours after the initial count. If radon daughters are interfering with the

analysis, complete the next step.

(15) If

radon daughters are interfering with the analysis, the actual contribution to

the count from alpha emitting transuranics may be estimated by using one or

more of the following methods:

a.

A counting instrument may be used that is

designed to discriminate the radon contribution.

b.

Plant-specific software such as a spreadsheet

may be used to calculate the radon contribution.

c.

A subject matter expert may be assigned to

perform the evaluation.

d.

The following equation may be used to estimate

the transuranic concentration from the follow-up count on line 15. Consult with RP supervision on desired decay

times between counts.

|

where: |

|

|

|

ncpmtr= |

Net count rate due to alpha emitting transuranic nuclides |

|

|

ncpm1= |

Net count rate from initial analysis |

|

|

ncpm2= |

Net count rate from follow-up analysis |

|

|

Δt= |

Time between analyses, minutes |

|

|

0.017= |

Decay constant for a 40 minute half-life, min-1 |

|

e.

Record the radon compensated results (ncpmtr)

in the ncpm column on line 15. Complete

line 15 using the radon compensated results.

This is only an estimate and should not be used for record values. Only the results after full radon decay

should be used for record results.

(16) Record

long-lived analysis data after the sample has decayed ≥ 72 hours using the same steps as described for the initial α analysis. This analysis should provide the basis for

the record value of fDACα if radon daughters interfered with the

initial analysis.

Attachment 2: Instructions to Complete Airborne

Radioactivity Worksheet (continued)

Section

IV: Summary

This section is used

to record the final DAC values from the sample as described below.

(17) Record

the value for fDACβγ as follows:

a.

Record gamma spectroscopy results if

performed. Attach the gamma spectroscopy

printout or reference the analysis reference number used by the site.

b.

Record the results from the beta-gamma analysis

from Section II if gamma spectroscopy was not performed.

c.

Record ND if βγ activity was not detected.

(18) Record

the value for fDACα as

follows:

a.

Record less than 0.1 if alpha activity was not

detected.

b.

If alpha activity was detected, record the

long-lived results from (16).

c.

Record n/a if alpha analysis was not performed.

(19) Record

the fDACTotal by summing the values from (18) and

(19).

(20) Submit

the results for review and approval.

Immediately notify RP supervision to alert them to any one of the

following conditions:

a.

The βγ/α Ratio is less than 30,000 in an

Alpha Level 1 Area

b.

The βγ/α Ratio is less than 300 in an

Alpha Level 2 Area

c.

The βγ/α Ratio is less than or equal to 50

in an Alpha Level 3 Area

d.

Beta-gamma activity was not detected but alpha activity was detected.

Attachment 3: TRU Multiplier Based on Co-60 and Am-241

Attachment 4: Alpha

Analysis Requirements for Samples from Alpha Level 2 Areas

Purpose

This attachment

provides instructions for determining when a particulate air sample from an Alpha

Level 2 Area must be analyzed for alpha emitting transuranics; three options

are available as follows:

Option

1 – Perform alpha analysis on all particulate air samples or on all

particulate air samples with a measured fDACβγ greater than a

site-specified value, e.g. 0.025 DAC.

Option

2 – Perform an alpha analysis on a particulate air sample that indicates a

Total DAC ≥ 1.0 DAC when

applying a TRU Multiplier as determined by site characterization.

Option

3 – Perform an alpha analysis on a particulate air sample that indicates a

Total DAC ≥ 1.0 DAC assuming

the most restrictive alpha emitter (e.g. Am-241) and the most restrictive beta

emitter (e.g. Co-60 or Cs-137) expected in the nuclide mixture.

RP supervision at each

plant is responsible for directing supplemental RP personnel on the acceptable

options to use based on plant procedures.

Option 1

For particulate air samples from Alpha Level 2

Areas meeting site-specific criteria, record both the beta analysis results and

the alpha analysis results on Attachment 1.

Use these values to determine the Total DAC.

Option 2

1.0 Multiply

the fDACβγ by the TRU Multiplier provided by site procedures, RWPs

and/or ALARA Plans.

2.0 If

the Total DAC is ≥ 1.0,

perform an alpha analysis and record the results using Attachment 1.

Option 3

1.0 If

this option is used, the βγ/α Ratio for the area where the air

sample was collected will be documented in plant procedures, ALARA planning

documents, and/or the RWP.

1.1

The βγ/α Ratio is normally determined

based on the nuclide mixture collected from loose surface contamination.

2.0 Record

the βγ/α Ratio on Attachment 1.

3.0 Use a graph to determine if alpha analysis

is required as described below. Graphs

may be based on assuming a Co-60 and Am-241 mixture (shown below) or based on

actual characterization of the nuclide mixture.

3.1

Locate the intersection of the following:

a. The

βγ/α Ratio for the area where the air sample was collected.

b. The fDACβγ measured from the air sample.

3.2

If the intersection is to the left of the line,

alpha analysis is required. Document the

analysis results on Attachment 1.

3.3

If the intersection is to the right of the line,

alpha analysis is not required.

Attachment 4:

Alpha Analysis Requirements for Samples from Alpha Level 2 Areas (continued)

Attachment 5: Sample Particulates and Iodine Using Standard

Air Sampler

1.0 Obtain

equipment listed below as needed:

·

Sample head

·

Particulate filter

·

Iodine Cartridge

·

Air Sampler

·

Sample label

·

Poly bags or equivalent

·

Sample tubing

2.0 Check

rubber O-rings on sampling head to ensure positive seals as required for the

model of head being used.

3.0 Place

filter paper into filter holder with collection side toward sample intake.

If the collection side is not indicated by the manufacturer, mark the

collection side with a pen or marker so that any subsequent analyses can be

performed on the collection side.

4.0 If

iodine sampling is required, then place new iodine cartridge into holder with

arrow pointing with direction of air flow. A dummy cartridge may be used if iodine sampling is not required

and the air sampler has been calibrated with an iodine cartridge.

5.0 Set

up sampler as shown below.

6.0 Place

sample inlet in a location representative of the desired sample; a location that is far enough from a contaminated surface

to prevent pulling surface contamination into the sample media.

Attachment 5: Sample Particulate and Iodine Using Standard

Air Sampler (continued)

7.0 For

grab samples, estimate the time required to obtain the minimum volume by

dividing the required sample volume by the flow rate; ensure units are

consistent and convert as needed.

CAUTION

Do not operate a sampler

where hydrogen may be approaching the Lower Explosive Limit (e.g. 2% to 4% H2). Notify industrial safety personnel as needed

for confirmation.

8.0 Turn

on the sampler and verify, or adjust, the flow rate to be within 20% of the

calibrated flow rate.

9.0 When

the predetermined sample time or longer has passed, then stop the sampler and

record the information as listed in section (6) on Attachment 1.

10.0 Remove

sample collection media and place in

a bag, exercising care to prevent cross contamination.

11.0 Determine

the sample volume by multiplying the sampling time by the observed sample flow

rate; ensure units are consistent and converted as needed.

Comments

Post a Comment